This is a High-efficiency grinder/polisher for wafers.

What can the High Precision Backside Wafer Thinning Machine do?

It can grind third generation semiconductor materials such as SiC, GaN,GaAs,.Si,ZnO.

This is a self-made grinding machine in China, and its performance has reached the world standard.

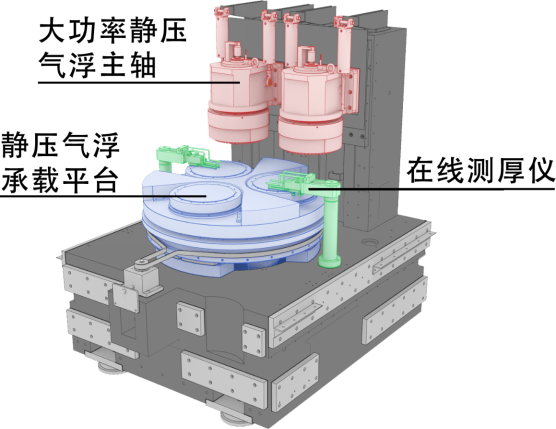

what does it consist of?

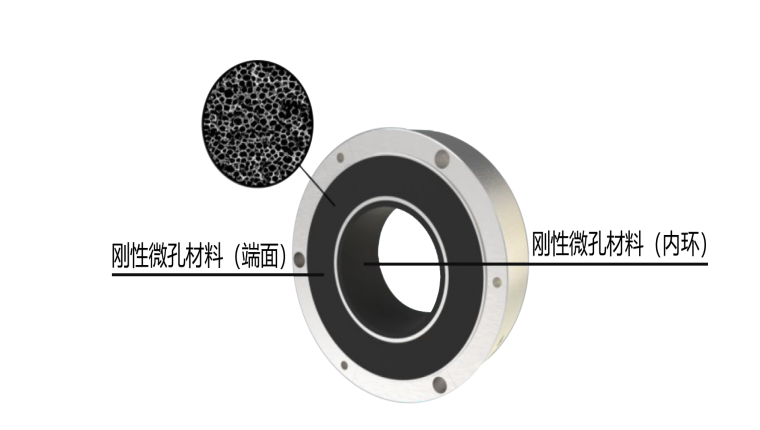

1.DL-ES55 Series Hydrostatic air-floating electric spindle。

Advantages: Air bearing has high rigidity, low vibration, low thermal expansion and small speed change.

Air-floating electric spindle adopts rigid microporous material as the air flotation block, and the spindle accuracy, life, air permeability and stability are in the forefront of the world spindle products.

2.Manipulator

3.Hydrostatic air bearing work turntable

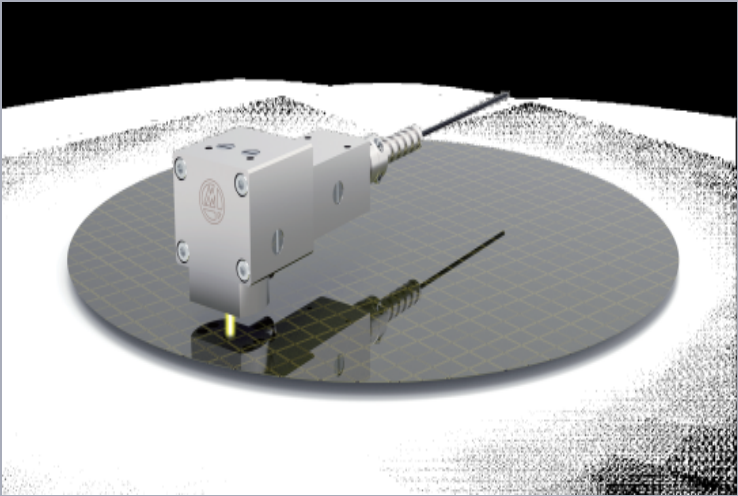

4.NCG(Non Contact Gauge)

advantage:

Non-contact, reduce fragmentation rate

More accurate, can measure wafer thickness after de-adhesive

Spec: Accuracy ≤ 1 μm

Repeatability 0.1 μm

Easy operation

Equipped with a touch-type liquid crystal display and GUI (Graphical User Interface) to improve the convenience of operation. The control screen can simultaneously display the processing status and equipment status.

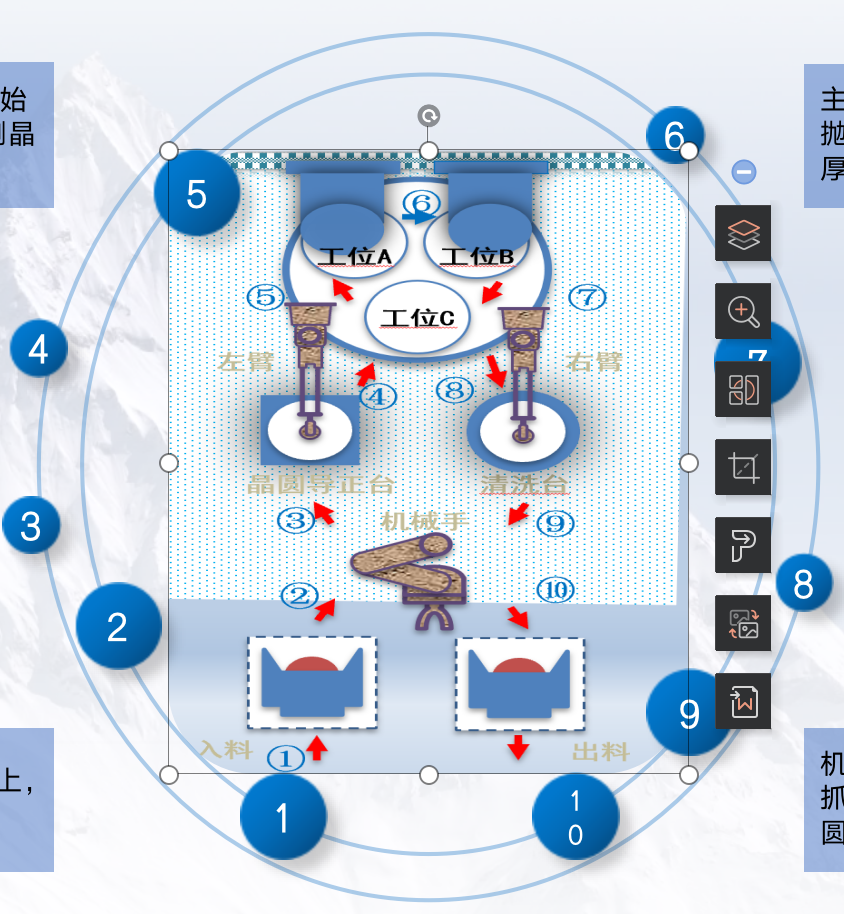

How it works?

1.Place the wafer cassette on the material table, and the material table automatically calibrates the wafer cassette.

2.The manipulator grabs the wafer from the wafer cassette and transfers it to the wafer guiding stage; the guiding stage positions and guides the wafer.

3.The main turntable rotates to station A for grinding, NCG detects the wafer thickness and automatically compensates the feed amount.

4.The main turntable rotates to station B for polishing, and NCG detects the wafer thickness and automatically compensates the feed amount.

5.The main turntable rotates to station C for cleaning and drying.

6.Robot returns the cleaned wafer to the wafer cassette.

+8613622378685

WeChat

WeChat

YouTube

Scan WeChat