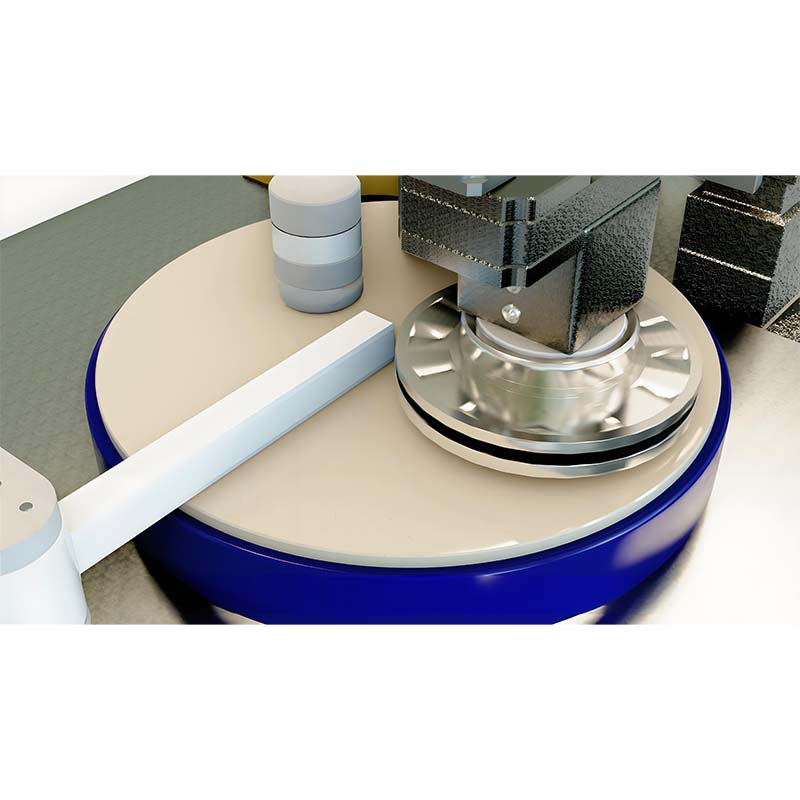

Chemical Mechanical Polishing (CMP), also fully known as Chemical Mechanical Polishing or Chemical Mechanical Planarization, is a global planarization process. Unlike simple physical grinding, CMP combines chemical etching and mechanical polishing to remove uneven surface materials and achieve atomic-level flatness.

When polishing products on aCMP polisher, the chemical components in the polishing slurry first undergo a mild chemical reaction with the materials on the wafer surface to soften them. Then, the polishing head of the CMP polisher applies pressure to the wafer, and the relative movement between the wafer and the polishing pad generates friction, which effectively removes the thickness of the wafer surface to achieve planarization.

A fully automatic CMP polisher consists of 5 major systems:

- Polishing System

- Cleaning System

- Endpoint Detection System

- Control System

- Transfer System

CMP polishers can polish metal materials (including interconnect layers such as Al, W, and Cu; barrier layers such as Ti, TiN, Ta, and TaN), dielectric layers (such as SiO₂, PSG, BPSG, SiNₓ, and Al₂O₃), and semiconductor materials (such as Si, GaN, SiC, GaAs, and InP).

Therefore,

Chemical Mechanical Polishing (CMP) is a global planarization process that combines chemical etching and mechanical polishing. It is a key process in ULSI (Ultra-Large-Scale Integration) production, with the machine containing 5 major systems and capable of polishing metal, dielectric, and semiconductor materials.