After wafer polishing, we often find a large number of residual particles on the surface. These particles usually come from two sources:

First, the polishing slurry contains a large amount of abrasives. Although these abrasive particles are extremely small, they have a certain degree of adhesion and will directly attach to the wafer surface after polishing.

Second, during the polishing process, friction occurs between the polishing medium and the product, generating cutting force. The solid particles of the product cut off from the product surface will be embedded into the wafer surface.

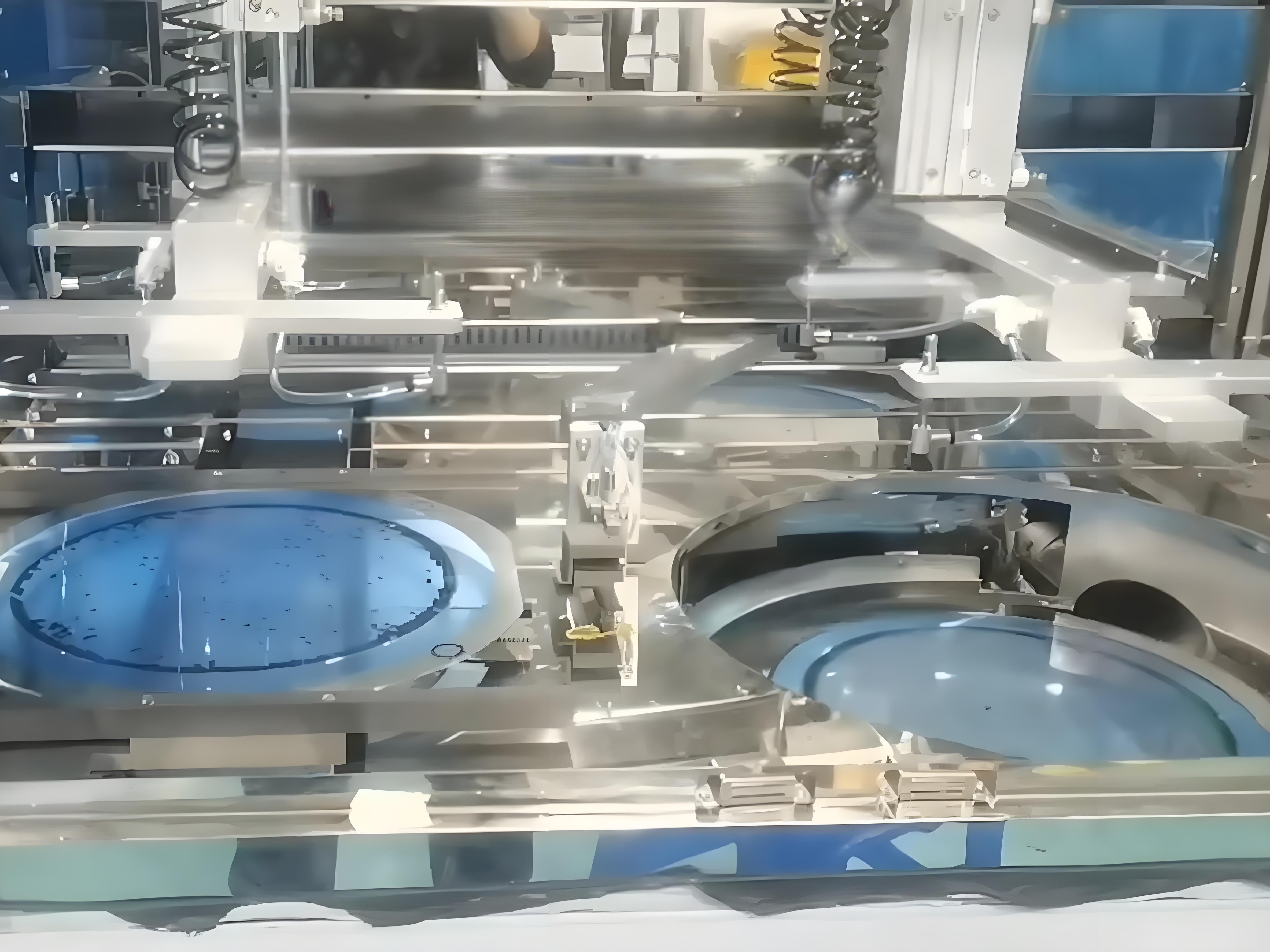

Since the above two situations can cause wafer surface contamination and lead to defects such as scratches, we usually use a brush cleaner to clean the wafer surface after CMP (Chemical Mechanical Polishing).

The brush cleaner uses PVA (Polyvinyl Alcohol) material, which is soft and will not scratch the wafer surface while effectively cleaning various particles on the wafer surface. In addition, we also recommend replacing the polishing pad regularly to reduce wafer contamination.

Scan WeChat