Full-Cycle After-Sales Service System and Operation & Maintenance Specifications for Wafer Grinding Machine

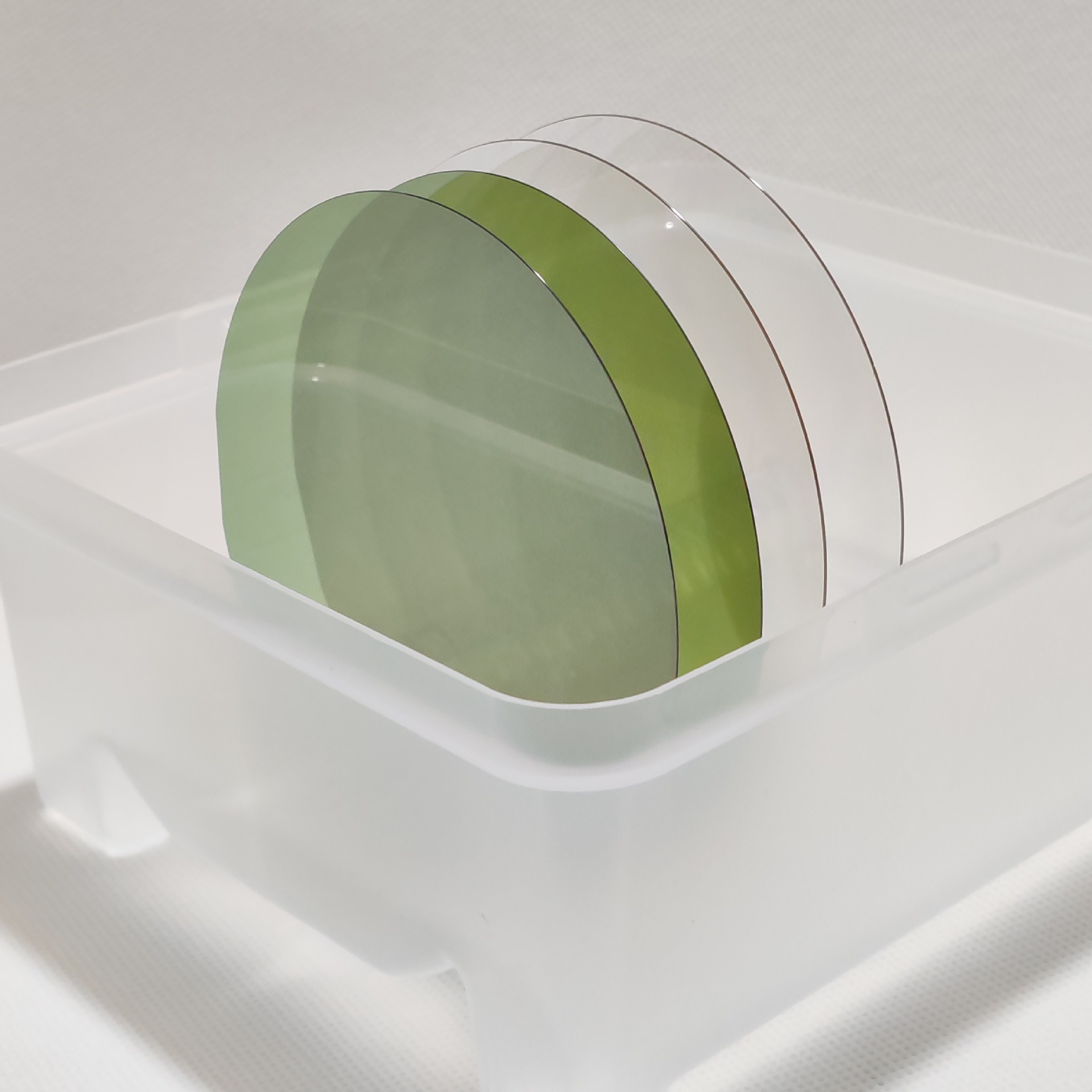

After each

Wafer Grinding Machine rolls off the production line, we provide a comprehensive after-sales service to ensure the customer’s normal operation.

During the commissioning and training of the Wafer Grinding Machine, the training content is delivered in modular sections. The basic operation module covers the equipment power-on self-test process, setting methods for grinding parameters (grinding pressure, rotation speed, time), wafer clamping and positioning skills, as well as operation scenarios of the emergency stop button.The professional commissioning module includes explanations of grinding wheel flatness calibration, debugging logic for matching grinding wheel grit sizes to different wafer materials, and prevention and correction solutions for edge over-grinding. The troubleshooting module focuses on teaching the identification and handling of common alarms (such as abnormal pressure and wafer offset), as well as the status inspection methods for key equipment components (such as the spindle and fixtures).The training process must be combined with practical demonstrations to ensure that the customer’s technical personnel can independently complete routine commissioning and simple fault handling.

The maintenance of the

Wafer Grinding Machine shall follow the principles of "regular inspection, precise maintenance, and prevention first". Daily maintenance includes cleaning wafer debris on the surface of the grinding wheel and vacuum chuck after each use, as well as checking the oil level and pressure of the hydraulic system.Weekly maintenance focuses on inspecting the wear condition of the grinding wheel, cleaning dust inside the equipment, and calibrating the accuracy of grinding parameters. Monthly maintenance involves lubricating and maintaining the spindle, inspecting the connection status of electrical circuits, and replacing hydraulic oil.For long-term maintenance, the flatness of the grinding wheel shall be tested and repaired every six months; a full equipment accuracy calibration shall be conducted every year, and aging seals and wearing parts shall be replaced.